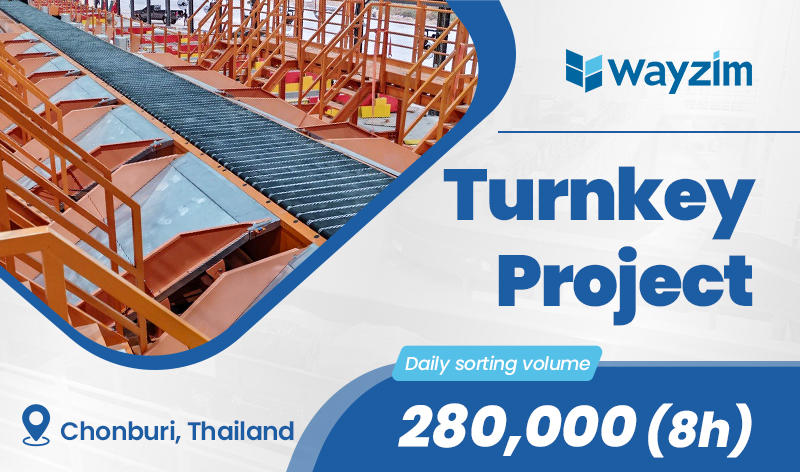

Project footprint: 900 ㎡. Daily sorting volume: 40,000 pcs (8 h). Nieuwegein, located in the Dutch province of Utrecht, is a critical logistics hub due to its central location and convenient transportation network. With increasing commercial activities and surging demands for online shopping, demands for e-commerce and daily parcel delivery have grown rapidly. The existing sorting modes cannot keep up with the growing parcel volumes, forcing enterprises to invest more in labor. This not only significantly increases labor costs but also harms sorting efficiency and accuracy. Furthermore, stricter regulations on environmental protection stipulated by Western European countries highlight the shortcomings of conventional sorting systems, particularly in their high energy consumption and inefficiency, placing increasing pressure on enterprises for environmental protection. In this case, the customer urgently needs an advanced automated and intelligent sorting solution, to enhance sorting efficiency, reduce operating costs, meet strict environmental protection requirements, and improve user experience, thereby achieving the sustainable development goal.

Project footprint

Maximum processing capacity of the system

Daily sorting volume

Fragile parcels require higher requirements for protection and flexibility during sorting. The conventional manual sorting method is insufficient in stability and consistency, making it difficult to meet high standards of flexible sorting.

In developed European regions, labor costs are generally high. The conventional manual sorting mode increases the operational burdens of enterprises and makes it difficult to meet modern logistics demands for efficiency and accuracy.

Conventional sorting systems have high energy consumption and lack energy-saving designs, putting enterprises under greater pressure due to strict environmental protection policies.

To align with the development trend of green logistics, Wayzim customized an intelligent logistics system solution for the customer. Wayzim uses advanced technology and innovative designs to meet modern logistics demands, and works with the customer to shoulder corporate social responsibility in sustainable development. The system optimizes motor selection and incorporates an energy-saving mode, significantly reducing energy consumption while maintaining high-performance operations.

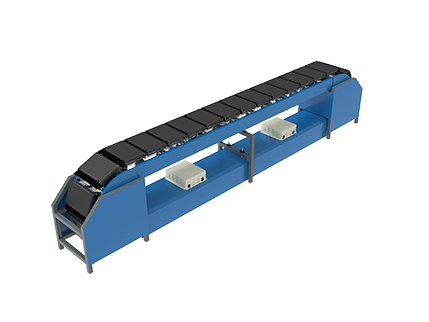

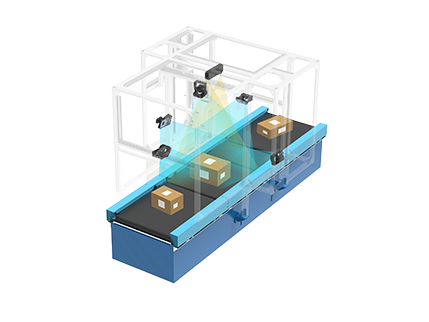

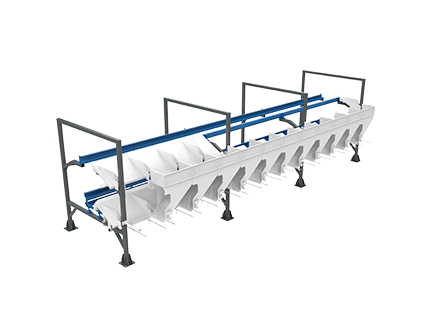

The entire system includes one 300 Linear Sorter, 26 damping roller chutes, 2 automated infeed systems, and 2 dynamic DWS systems. The system uses a modular design, ensuring efficient collaboration among all equipment and meeting the demands for efficiently processing the transfer of a large volume of parcels.

This solution not only significantly improves sorting efficiency and accuracy but also reduces parcel damage rates effectively. For the demands for processing fragile parcels, the solution improves a series of designs to ensure high-standard flexible sorting. The damping roller chutes are specifically designed to control the sliding speed of parcels, ensuring parcel integrity during conveying. In addition, the sorter uses flexible sorting technology to provide extra protection for fragile items, minimizing damage risks and meeting requirements in diverse logistics scenarios.