Project footprint: 9,000 ㎡. Daily sorting volume: 280,000 pcs (8 h). The project is located in Chonburi, a major economic center in Thailand. Under the Eastern Economic Corridor (EEC) initiative, Chonburi is transitioning into a "smart city". As Chonburi is a hub for logistics, aviation, digital innovation, and tourism in Thailand, after careful consideration, the customer decided to collaborate with Wayzim. Wayzim planned and established a modern logistics sorting center in this strategic location, meeting logistics demands for freight and supply chain operations.

Project footprint

Processing capacity of the small parcel sorting system

Daily sorting volume

Chonburi is adjacent to industrial parks and commercial zones with a high population density, resulting in high parcel processing demands. However, manual sorting is slow in speed and has a high mis-sorting rate, affecting overall logistics efficiency.

With rising labor costs, conventional logistics sorting modes pose significant cost pressure to enterprises, which reduces the enterprises‘ profits and hinders their sustainable development.

Wayzim provided a total integrated logistics solution for the customer, and replaced manual labor with automated sorting equipment, effectively addressing the sorting challenges of low sorting efficiency and accuracy due to manual sorting in the local area.

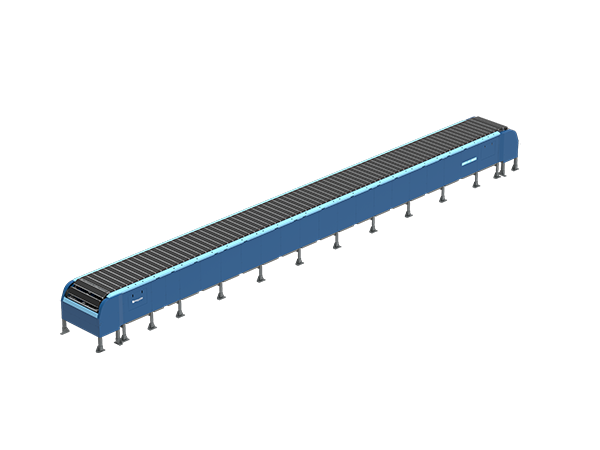

Unloading area: This area uses a two-in-one unloading mode, enabling the loading and unloading speeds for a large volume of parcels to match the multi-line parallel features of the matrix pivot wheel sorting area. In the two unloading lines, one is equipped with a dynamic DWS system to simultaneously collect parcel information and weight data.

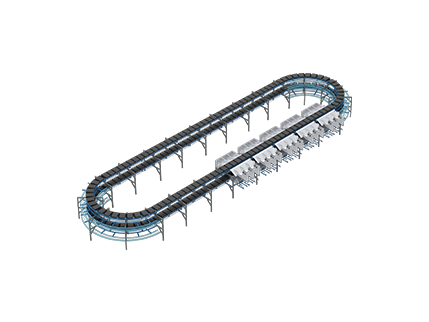

Small parcel collection and sorting areas: Small parcel consolidation bags are diverted to two infeed lines through matrix pivot wheel sorters. The consolidation bags are manually unpacked, and small parcels are accumulated in the unpacking chutes for efficient infeed by operators, maximizing manual infeed efficiency. The small parcel sorting area is equipped with 1 single-layer double-area cross belt sorter, 14 semi-automated infeed conveyors, 202 discharge points and chutes, and 2 Cross Belt Sorter 5-sided Barcode Scan Tunnels, achieving a sorting efficiency of 22,000 pph.

Fine sorting loading area: The fine sorting loading line mainly uses manual sorting, and uses a narrow belt sorting mode to replace the conventional automated pivot wheel sorting mode. This sorting method supports flexible sorting of all types of parcels, reducing mis-sorting rates and improving sorting efficiency with a theoretical capacity of no less than 6,000 pph.