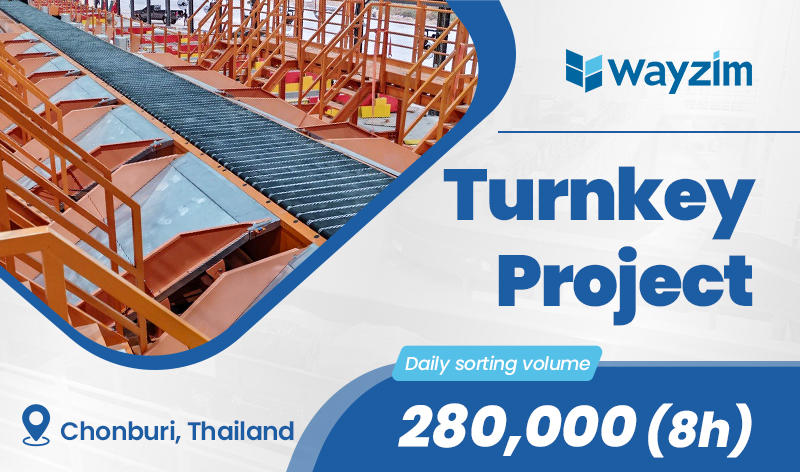

Project footprint: about 30,000 ㎡. Daily sorting volume: 1,280,000 pcs (8 h). The customer is a leading e-commerce platform in Southeast Asia, and is known for offering diverse products and convenient shopping experiences. Its business covers several surrounding countries and regions. As a rapidly growing e-commerce giant, the customer faces a surge in business volume, particularly during promotional periods when orders and parcels skyrocket. This increase has placed higher demands on sorting efficiency. Wayzim equipped the customer with a systematic intelligent logistics solution. With high sorting efficiency and excellent system integration, Wayzim helped the customer streamline the entire sorting process. The solution can meet demands for processing diverse orders while effectively reducing costs, support the sustainable development of the customer's business, and help the customer deliver faster and more reliable services.

Project footprint

Maximum processing capacity of the system

Daily sorting volume

Cross-border e-commerce platforms require high capacity for processing small parcels, but current sorting modes can hardly meet.

Intense industry competition makes delivery timeliness a core factor for service quality and competitive advantage in the market.

A high mis-sorting rate may lead to frequent incorrect, missing, or delayed deliveries, directly affecting consumers\‘ shopping experiences and increasing the hidden costs.

The intelligent logistics solution provided by Wayzim consists of various types of automated sorting equipment, together creating a complete automated sorting process.

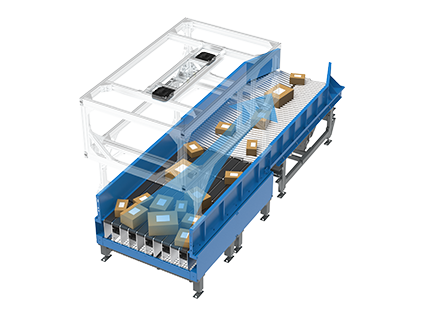

Unloading area: 16 telescopic unloading systems, 8 two-in-one matrix pivot wheel sorting systems, 10 large parcel DWS sorting systems, and 24 matrix large parcel chutes.

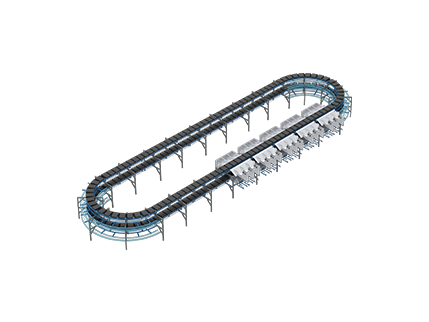

Small parcel sorting and collection areas: 2 parcel collection and sorting systems, 10 2D Bulk Flow Singulator Systems, 4 automated infeed systems, 20 pivot wheel sorting systems, and three-layer and single-layer cross belt sorters.

Loading area: three-layer staggered chutes.

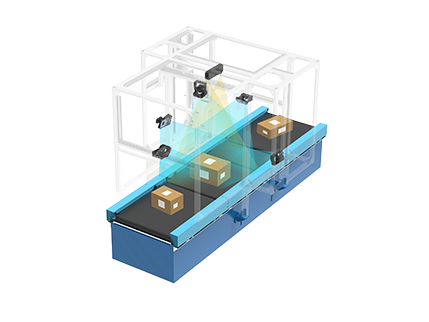

The sorting process begins in the unloading matrix area. The telescopic automated unloading system automatically conveys parcels to a two-in-one merging device. After the 2D Bulk Flow Singulator singulates the disorderly parcels, the Dynamic DWS System collects parcel volume, parcel weight, and barcode information. Roughly sorted small parcels enter the cross belt sorter for efficient sorting, while large parcels are roughly sorted by the matrix pivot wheel system and then further finely sorted by parcel sorters before manual palletizing and loading. The entire solution is divided into areas based on their functions, and the sorting equipment works collaboratively to achieve fast and accurate parcel sorting, significantly improving overall operational efficiency.