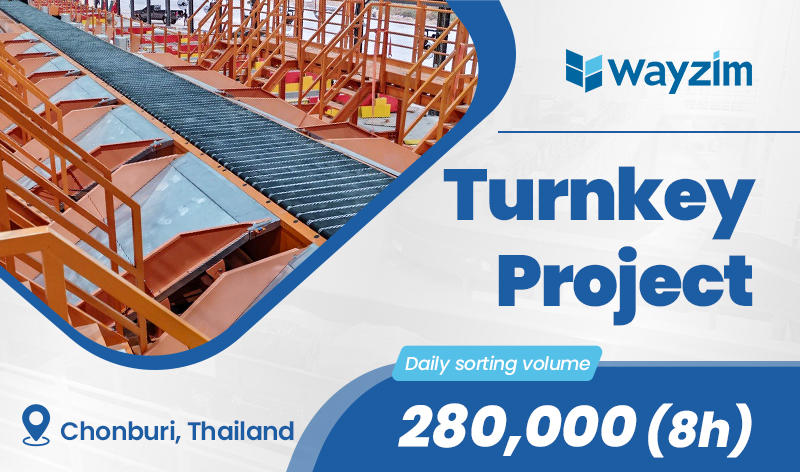

Project footprint: 30,000 ㎡. Daily sorting volume: 320,000 pcs (8 h). The project is located in Samut Prakan, Bangkok, Thailand. The customer is a major cross-border e-commerce company in Thailand. To improve the transfer efficiency of parcels and respond more swiftly to international market demands, the customer constructed a new automated logistics sorting center in Thailand, covering an area of 30,000 ㎡. Wayzim planned and implemented a totally integrated logistics solution for the customer. The matrix pivot wheel sorting area and double-layer cross belt sorting area are used as the core functional areas, achieving sorting capability for a high throughput of parcels. The daily parcel processing volume can reach 320,000 pieces, which significantly improves sorting efficiency, meets the customer's needs for intelligent sorting, and supports the rapid growth of express delivery services.

Running speed of the cross belt sorter main line

Maximum daily processing volume

Peak processing capacity of the pivot wheel sorting system

With the rapid development of cross-border e-commerce, conventional manual sorting is inefficient and no longer meets the customer‘s demands for international express delivery services that involve a wide range of aspects and complex processes.

Manual sorting efficiency is low and may cause mis-sorting. Mis-sorting leads to secondary sorting, which prolongs processing time and increases logistics costs.

The instability caused by manual sorting increases the possibility of parcel damage during transport. The customer is urgently seeking a more efficient and safer sorting mode to reduce the parcel damage rate and enhance logistics service quality.

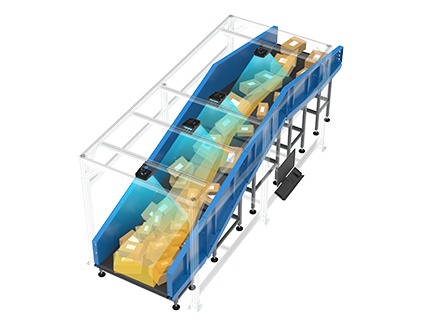

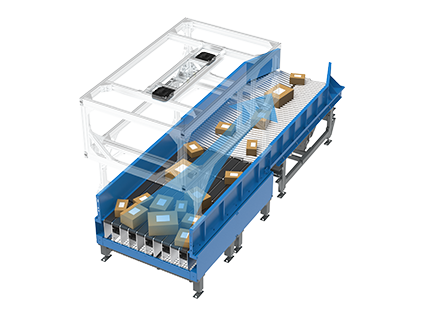

The project combines automated matrix pivot wheel sorting systems with high-speed sorting systems. Mail sacks and parcels are directly transferred by the automated matrix pivot wheel area, small parcels are sorted by the upper layer of the high-speed double-layer one frame two-carrier cross belt sorter, and large parcels are sorted by the lower layer. In this way, all types of mail and parcels can be automatically processed. With 3D Bulk Flow Singulator and 2D Bulk Flow Singulator systems, the project can achieve integration and automation of parcel loading, unloading, singulation, sequencing, sorting, collection, and transferring by roll containers in the whole process.

Matrix pivot wheel sorting area: In this area, 10 automated pivot wheel sorting mainlines operate collaboratively to roughly sort large batches of parcels from the unloading area, ensuring the smooth entry of upstream parcels into the sorting process. The mainline running speed can stably maintain at 2 m/s.

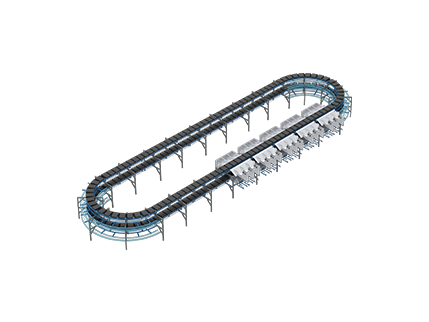

Double-layer cross belt sorting area: This area includes a double-layer one frame two-carrier cross belt sorter, with a total loop length of 842 m. Small parcels are diverted to the upper layer of the cross belt sorter, while large parcels are diverted to the lower layer, implementing efficient and simultaneous sorting of both small and large parcels by using one set of equipment.