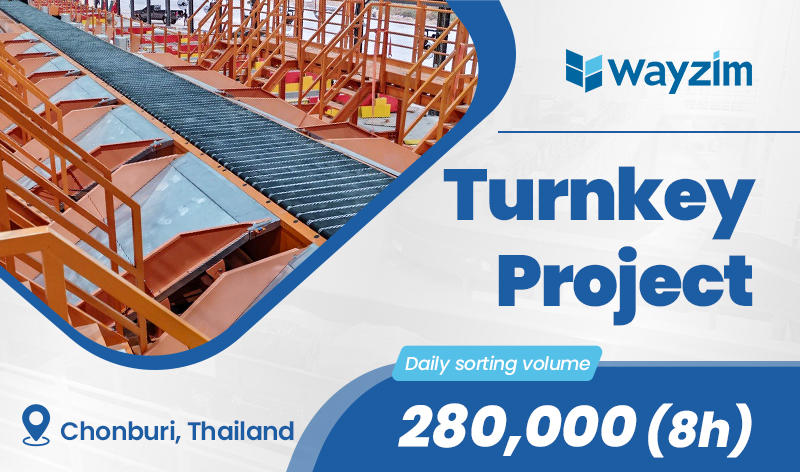

Project footprint: about 9,200 ㎡. Daily parcel processing volume: 192,000 pcs (8 h). The project is located in Taguig, Philippines. Taguig is a rapidly developing city in Metro Manila and is known for its modern urban planning and its role as a major business, financial, and residential center. With the rapid growth of the regional economy and e-commerce industry, the daily parcel processing volume at the sorting center continues to climb, placing higher demands on sorting efficiency. In this case, conventional manual sorting modes are becoming obsolete. To address issues such as low manual sorting efficiency, high labor intensity, and increasing costs, Wayzim planned and implemented an automated logistics solution for the customer. By using advanced logistics equipment and sorting technologies, the project significantly improved the operational efficiency of the sorting center, reduced labor input, and notably lowered operating costs.

Project footprint

Maximum processing capacity of the system

Daily sorting volume

The conventional manual sorting mode has low sorting efficiency and a high mis-sorting rate, which cannot meet the sorting efficiency demands of logistics during peak flow periods.

Manual sorting requires frequent handling and manual operations, leading to high labor intensity and repetitive tasks. This not only causes employee fatigue but also requires a significant labor force, further increasing labor costs.

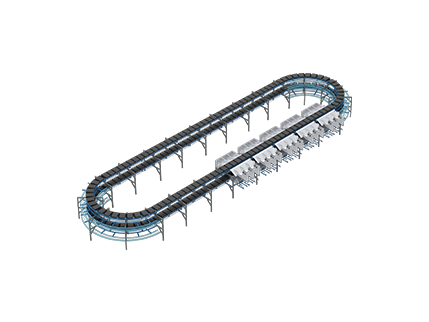

Based on the customer’s needs and actual situation, Wayzim planned an automated logistics solution based on a single-layer double-area cross belt sorter, achieving a daily sorting volume of 192,000 parcels (in 8 hours).

Unloading area: 2 automated unloading lines, and 7 manual unloading lines.

Small parcel sorting area: 1 single-layer double-area sorter.

Loading area: 6 manual loading lines, and 1 set of manual sorting equipment for non-conforming items.

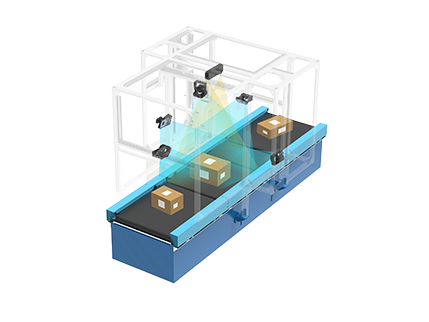

This solution establishes a basic conveyance network combining belt conveyor lines and matrix pivot wheel sorters. The system collects information including parcel weight, parcel volume, and barcode information through the dynamic DWS system, enabling efficient automated sorting of large and small parcels. Compared to conventional manual sorting, this automated sorting system optimizes the operation process in the distribution center, significantly improves operational efficiency and space utilization, reduces labor input, and provides the customer with an efficient, economical, and sustainable distribution solution.