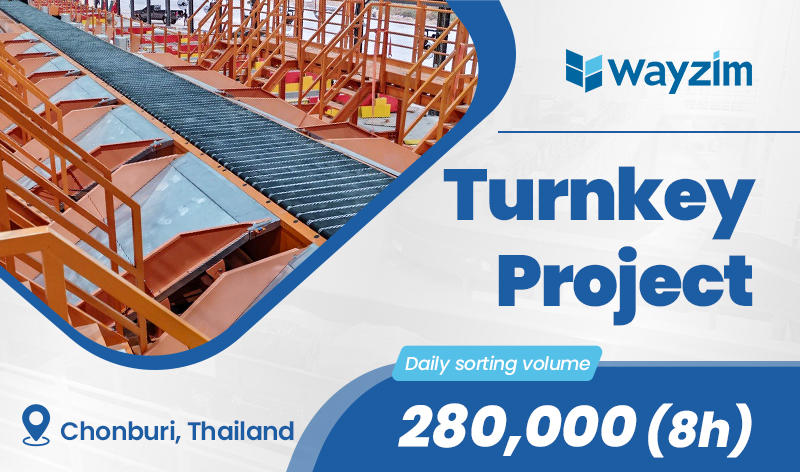

This project covers an area of approximately 130,000 ㎡, including a 10,600 ㎡steel grid platform in the warehouse. Daily sorting volume: up to 7 million pcs. The project is located in the Modern E-commerce Logistics Park of Huai'an District, serving as the logistics transfer center of northern Jiangsu. The project is near National Highway 233, the interchange of Huai'an East Expressway, and the Huai'an East High Speed Railway Station. The customer is a comprehensively leading logistics enterprise, providing office space, logistics sorting, warehousing, and site leasing services. This logistics transfer center leverages Huai'an's geographical advantages to provide efficient logistics services for the Yangtze River region and surrounding provinces. It has become a critical logistics node connecting the Yangtze River Delta and the whole Jiangsu province. In addition, the logistics transfer center will form a locational economic effect, attracting more logistics enterprises and related industries to Huai'an, promoting industrial agglomeration and development, forming a complete industrial chain, and enhancing regional economic development.

Running speed of the cross belt sorter main line

Maximum daily processing capacity

Peak processing capacity of the pivot wheel sorting system

Peak processing capacity of the small parcel cross belt sorting system

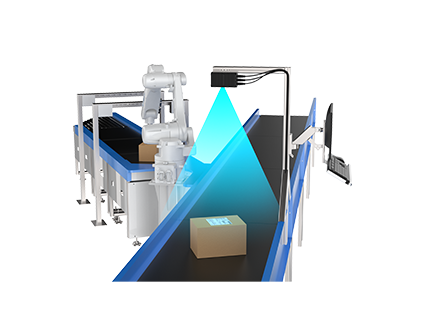

The customer needs automated sorting equipment, intelligent sorting system, and software system to extend the industrial chain and achieve the integration of e-commerce, express delivery, express transportation, and intelligent warehousing operations.

With the rising parcel volumes, the sorting center faces immense operational pressure, and needs automated sorting equipment urgently to improve sorting efficiency and ease the operational pressure.

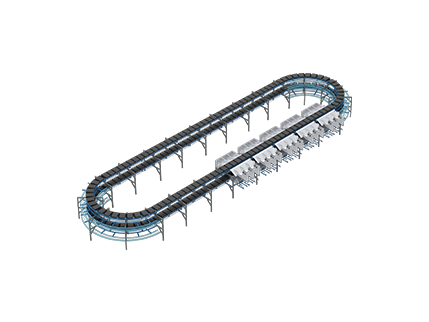

The project is located in a rectangular site with a U-shaped layout. Equipped with various automated sorting equipment independently developed by Wayzim, including automated sorting systems, automated unloading pivot wheel sorter lines, automated loading pivot wheel sorter lines, and double-layer small parcel cross belt sorting systems, the project can process up to 7 million parcels daily.

Unloading area: There are 31 unloading mainlines for rough sorting, with a mainline running speed of 2 m/s and a single-line processing capacity of more than 2,000 pph. The area also includes 22 carrier unloading locations, 2 return conveyor lines, 2 abnormal parcel return conveyor lines, 15 fine sorting loading mainlines, 2 automated large parcel security inspection lines, and 6 small parcel security inspection lines.

Small parcel sorting area: The area is equipped with 3 double-layer small parcel cross belt sorting systems. The systems use fully automated infeed modes, achieving a sorting efficiency of 180,000 pph.