In recent years, the rapid development of the express delivery industry in China has driven the growth of the intelligent logistics equipment industry.

According to the June 2023 China Express Delivery Development Index Report recently released by the State Post Bureau of the People's Republic of China, in the first half of the year, the express delivery volume exceeded 60 billion, with a year-on-year growth rate of over 17%. Express delivery business revenue is expected to exceed 550 billion yuan, with a year-on-year growth rate of about 11.5%[1].

The dramatic increase in the express delivery volume has prompted continuous improvement in the performance of automated sorting equipment of different structures to meet the rapidly changing market demands.

The Cross Belt Sorter independently developed by Wayzim uses a servo motor drive system, achieving a maximum operating speed of 2.5 m/s and a sorting error rate of ≤ 0.01%. The sorter is primarily used for the automated processing of medium and small-sized items in large express distribution centers. It can continuously handle small parcels, boxes, and cartons in large batches, efficiently sorting items from light envelopes to goods weighing up to 50 kg.

▲ Cross Belt Sorter (Two-Level)

Project Application

Introduction to the Case

Project case: A top express delivery company in Yiwu, Zhejiang, China (turnkey project)

Delivery time: October 2021

Project scale: This project covers an area of approximately 96,000 square meters. The peak processing capacity of one Cross Belt Sorter is up to 60,000 pcs/h (with an operating speed of 2.52 m/s required by the project).

Project configuration: 2D Bulk Flow Singulators, fully automated Pivot Wheel Sorter loading lines, and two-level four-zone Cross Belt Sorters.

▲ Cross Belt Sorter (Local)

Solution Performance

The city where this project is located has the world’s largest small-commodity market. Its express delivery volume ranks among the top in China and the parcels are mainly small and medium-sized ones. The customer stated that its traditional sorting process was inefficient and capacity optimization was needed after the relocation.

In this project, Wayzim not only established warehouses A and B and used automated sorting equipment in the full process on a large scale, but also equipped two-level four-zone Cross Belt Sorters. The sorters mainly handle lightweight and small-sized parcels. By parcel consolidation, they have reduced the loss rate of small parcels. The peak daily processing efficiency of the project can reach 10 million parcels.

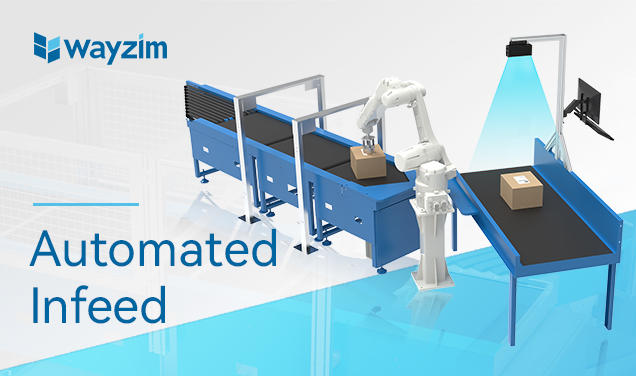

The Cross Belt Sorter systems, with Cross Belt Sorters as the core, consist of conveyor belts, infeed stations, sorting carriers, barcode scanning and weighing systems, code complement systems, and sorting discharge points. The systems are capable of conveying and sorting parcels in large batches for a long time. The core actions include identification (visual recognition system) and tracking control (mechanical conveying system). The main line supply uses unloading stations for surged goods, reducing the investment in disposable equipment.

Operating Principle

The sorting carriers are driven along the circular main line. When the carriers pass through the Cross Belt Sorter 5-sided Barcode Scan Tunnel, the tunnel reads the barcode information. The carriers obtain sorting instructions and move to the specified sorting locations. Meanwhile, the driving devices on the sorting carriers rotate the belts to sort and send parcels to target discharge points. The parcels flow into consolidation bags. After a consolidation bag is full, a barcode label is attached to the bag and the bag enters the loading process through the parcel return line.

▲ Operating Process

Solution Features

Efficient Sorting Process

1. Optimized space

The two-level design can fully utilize the vertical space of the site and the multi-zone infeed method can make the most of the horizontal space through the circular conveyor line. By optimizing the spatial layout, the overall sorting process is configured appropriately, meeting the demand for multiple sorting paths.

2. Optimized efficiency

Power sources are used to enhance efficiency. Each carrying unit uses a motor to drive a belt that can operate bidirectionally, to support both parcel infeed and discharge. The circular conveyor line is driven by linear motors. Each sorting carrier is equipped with a small belt conveyor (driven by a motorized roller), which supports high-speed sorting of 50 kg goods. The theoretical efficiency of one infeed section with a line speed of 2.5 m/s can reach 24,000 pcs/h.

Accurate Sorting Process

1. Improved reading accuracy

The visual recognition devices independently developed by Wayzim form a Cross Belt Sorter 5-sided Barcode Scan Tunnel, which can be used for small parcels like envelopes and ultra-thin items. Through the high-precision barcode/QR code recognition algorithm based on high-resolution images built into the cameras, the tunnel can detect and recognize barcodes/QR codes at a high speed accurately even if they are damaged, wrinkled, distorted, tilted, or blurred.

2. Improved processing accuracy

During system operation, intelligent logistics vision can read barcodes/QR codes quickly, parse the barcode information, upload the information to the customer’s server, obtain the target discharge points for express parcels, and guide sorting carriers to unload the parcels to the correct discharge points, with a sorting accuracy rate of 99.99%.

To ensure that the sorting accuracy meets the design goal, this project is also equipped with a manual code complement process, where operators complement codes manually to set the target discharge points for parcels.

Cost-effective and Flexible Deployment

1. Simple structure for easy service and maintenance

It takes only a few minutes to disassemble and replace a load unit, helping meet updated and upgraded project demands in a timely manner.

2. Flexible adjustment and configuration of deployment parameters

The parcel infeed channels can be enlarged, the distance to the discharge points can be shortened, and the width of the discharge points can be flexibly set. Adjustable sorting speed and selectable unloading speed empower high discharge accuracy based on the size and specifications of goods.

Therefore, the Wayzim Cross Belt Sorter system plays an important role in large hub express distribution centers by sorting a large volume of parcels efficiently and continuously, and conveying and transferring parcels properly, efficiently, and flexibly.

Summary

After years of technology accumulation, Wayzim has delivered over 940 Cross Belt Sorter systems[2] to customers, which are widely applied in warehousing and express centers. With the shortage of labor resources and the rising human resource and training costs, the costs of logistics real estate are increasing.

Therefore, space utilization efficiency has become an important assessment indicator in the express logistics industry, driving more customers to choose cross belt sorter systems with high stability and cost-effectiveness. Replacing manual sorting with automated sorting to achieve a dual improvement in efficiency and accuracy has become a necessary path for modern logistics.

*Data sources:

[1]: Official account of China Economic Net. The Express Delivery Industry Grows Steadily.

http://www.ce.cn/cysc/newmain/yc/jsxw/202307/19/t20230719_38637705.shtml

[2]: Wayzim Annual Report 2023